What makes our AI-enabled WMS different? It doesn't rely on IoT, robotics, or real-time device automation. Instead, it uses the data you already have—like orders, stock levels, staff shifts, and historical trends—to drive smart decisions across your warehouse.

Here’s how it works:

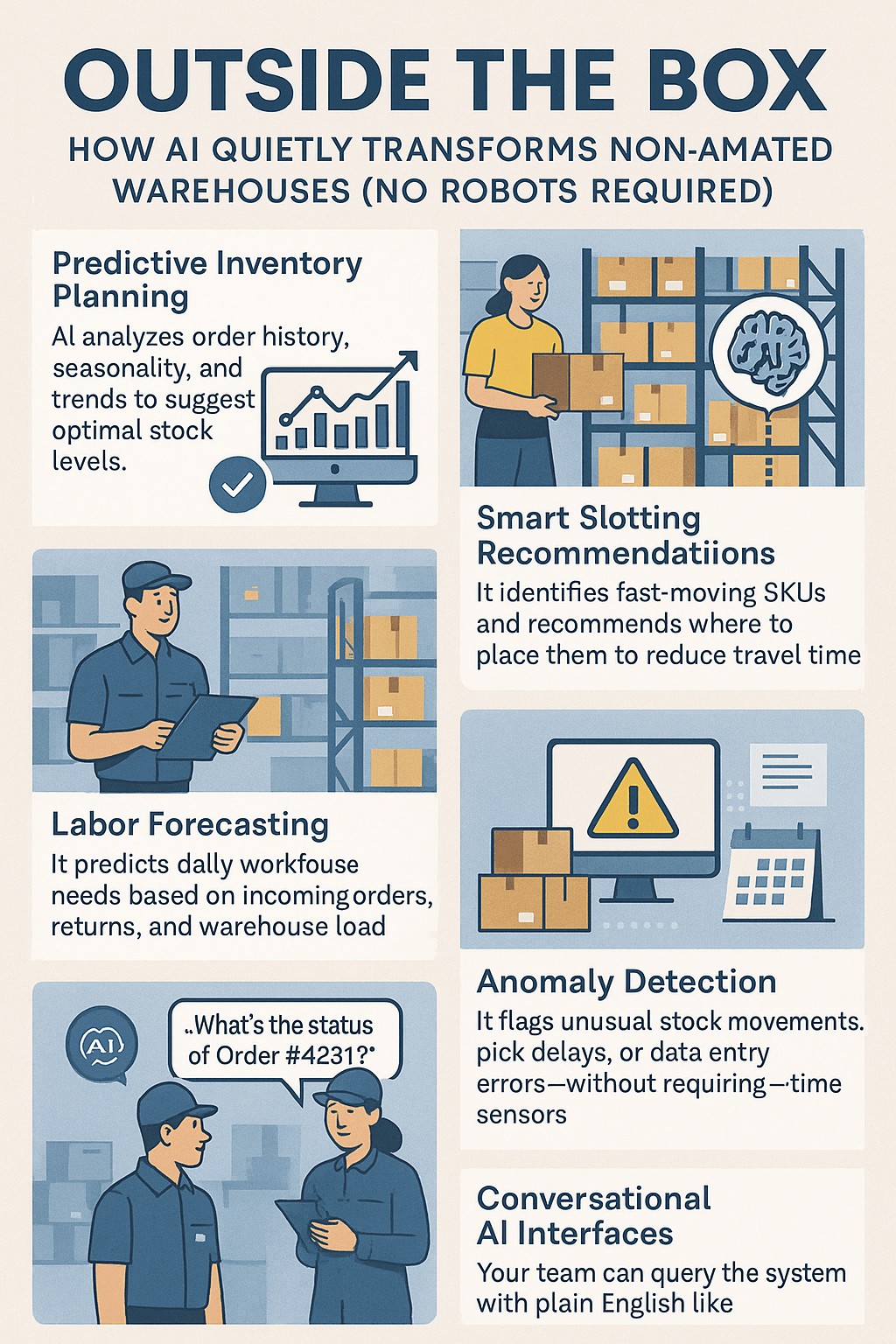

Predictive Inventory Planning – AI analyzes order history, seasonality, and trends to suggest optimal stock levels.

Smart Slotting Recommendations – It identifies fast-moving SKUs and recommends where to place them to reduce travel time.

Labor Forecasting – It predicts daily workforce needs based on incoming orders, returns, and warehouse load.

Anomaly Detection – It flags unusual stock movements, pick delays, or data entry errors—without requiring real-time sensors.

Conversational AI Interfaces – Your team can query the system with plain English like: “What’s the status of Order #4231?”

The Surprising Power of AI-Powered Inventory Management (No Sensors Required)

When most people picture AI-powered inventory management, they imagine futuristic warehouses packed with robots and sensors. But the real surprise? You don’t need any of that to see dramatic improvements. In fact, AI demand forecasting and inventory optimization can transform even the most traditional, non-automated warehouses—no robotics or IoT required.

Here’s how it works: AI algorithms dig deep into your historical sales, seasonal trends, promotions, and even market shifts. By crunching this data, AI produces highly accurate demand forecasts. The result? Fewer stockouts, less overstock, and inventory levels that are “just right.” Research shows that businesses using AI forecasting have cut errors by as much as 50%, with forecast accuracy gains ranging from 20% to 50%. That’s not just theory—it’s happening across industries, even in warehouses running on legacy WMS or ERP systems.

I remember visiting a warehouse where the manager was scratching his head over a mountain of overstock that had been building up for three years. If they’d had AI-powered inventory management, that pile would have been flagged months (if not years) earlier. Instead, they relied on gut feel and spreadsheets—tools that just can’t keep up with today’s complexity.

What’s really exciting is that you don’t need real-time data feeds or expensive hardware upgrades. AI can mine your existing transactional and historical data, producing actionable recommendations for replenishment and stocking. Many leading platforms now offer plug-in predictive analytics tools that integrate directly with legacy systems, making adoption surprisingly simple. Studies indicate that by 2025, 74% of warehouses will use some form of AI, driven by these practical, low-barrier solutions.

As Dr. Emma Torres puts it:

“AI-based demand forecasting is redefining what’s possible for traditional inventory management.”

So, whether you’re looking to boost demand forecasting accuracy, reduce carrying costs, or simply avoid the pain of overstuffed shelves, AI-powered inventory management offers a powerful, sensor-free path forward. The key is leveraging the data you already have—no robots required.

Slotting, Picking, and the Secret Art of Data-Driven Optimization

When most people picture AI-powered inventory management, they imagine robots zipping around a warehouse. But the real magic of smarter slotting strategies often happens in places where the only automation is a rolling cart and a determined picker. AI can quietly transform even the most traditional, human-operated warehouses by analyzing product velocity and order patterns—no robots required.

Here’s how it works: AI reviews historical order data, tracking which items move fastest and when. It then recommends slotting top sellers closer to packing zones. This simple change can slash pick times dramatically. I’ve seen it firsthand—my own team once shaved three hours off daily pick times just by following AI slotting suggestions based on transactional data. The step counter may protest, but your team’s feet will thank you.

Research shows that slotting optimization with AI can reduce picking route times and human travel distance by up to 30%. That’s not just a statistic; it’s fewer errors, less fatigue, and a smoother workflow at the end of every shift. The beauty of AI-powered inventory management is that it doesn’t demand expensive automation. Instead, it leverages the data you already have, making smarter decisions about where to place inventory for maximum efficiency.

Small changes—like reordering row layouts or adjusting shelf assignments—can yield dramatic time savings. These tweaks are often the lowest-hanging fruit for immediate efficiency gains in warehouse management. And while it might sound simple, the impact is real. As Jesse Palmer, Operations Manager, puts it:

"The fastest hands in the warehouse usually follow a data-driven map."

It’s not about replacing people with machines. It’s about using smarter slotting strategies to empower your team, cut down on wasted steps, and reduce costly picking errors. AI analyzes order trends and item velocity, suggesting item placement that improves picking routes—all without automated robots. Sometimes, all it takes is a willingness to shuffle inventory and listen to the numbers. Not every optimization requires a tech overhaul; sometimes, it’s just about making better choices with the data at hand.

Warehouse Chatbots: Why Talking to Your WMS Isn’t Futuristic (It’s Now)

When I first heard about chatbot warehouse interaction, I’ll admit—I pictured something out of a sci-fi movie. But the reality is much simpler, and honestly, a lot more practical. AI-powered chatbots are already transforming warehouse management in places you wouldn’t expect, and you don’t need robots or fancy hardware to get started.

Here’s what’s happening: Natural Language Processing (NLP) lets warehouse teams interact with their WMS just by typing or speaking. I’ve seen staff ask, “What’s our stock on this SKU?” and get an instant answer, no digging through menus or spreadsheets required. Voice commands are especially helpful for team members who aren’t tech-savvy—adoption goes up, stress goes down. It’s a win for everyone.

What really stands out is that there’s no need to overhaul your workflows. The software just becomes more approachable. One warehouse lead told me their team now queries delays or checks stock live, sidestepping the old, clunky report processes. It’s a small change on the surface, but it’s huge for day-to-day productivity.

These AI-powered inventory management tools can do more than just answer questions. They handle batch logs, process queries, and even guide staff through inventory audits. Moving from spreadsheets to conversation is the UI leap most warehouse folks never knew they needed.

Research shows that AI chatbots make warehouse management friendlier for human operators, boosting both adoption and productivity. They don’t replace people—they support them, especially in manual or non-automated environments. And because chatbots work with your existing WMS, there’s a lower barrier to tech adoption, even for multi-lingual or high-turnover teams.

As Sasha Rodin put it:

“If your WMS is hard to talk to, your people won’t use it. AI chatbots are the secret ingredient.”

With operational improvements AI brings, staff can interact with their WMS via chat or voice—“Show me delayed orders,” for example—improving speed and user satisfaction, all without hardware changes. It’s not about the future. It’s about making warehouse tech work for people, right now.

Spotting Trouble Before It Hits: AI-Driven Reporting & Anomaly Detection

When most people think of AI in warehouse management, they picture robots zipping around, but the real magic often happens quietly in the background. Anomaly detection AI is a perfect example. Instead of relying on real-time sensors or expensive automation, this technology sifts through system logs, batch data, and historical transactions to flag issues before they spiral out of control. It’s a subtle shift, but the impact can be huge.

Take our own experience: we once had a persistent data mismatch in our inventory records. It wasn’t obvious—no alarms, no flashing lights. But our AI-powered inventory management tool caught the inconsistency, flagged it, and helped us resolve the issue before it affected our bottom line. That’s the kind of proactive insight that keeps you ahead, not just playing catch-up.

Research shows that AI anomaly detection can reduce error-driven costs in inventory systems by up to 20%. It’s not just about catching fraud or mismatches, either. Predictive analytics can identify process bottlenecks or slowdowns, giving you the chance to fix problems before they become expensive headaches. As Priya Chatterjee, a Supply Chain Analyst, puts it:

“AI excels at catching what human eyes gloss over.”

What’s especially appealing is how accessible these tools are. Modern WMS add-ons and cloud plug-ins bring anomaly detection AI to legacy systems, so you don’t need to overhaul your entire operation. Batch-driven reporting fits perfectly in non-automated environments, making it possible to spot trends and outliers using only the data you already collect.

By acting on AI-driven insights, you can keep audit issues at bay and lower the risk of costly process breaks. Studies indicate that AI-driven process optimization has led to service level improvements of up to 65% in some logistics businesses. The best part? All of this happens without the need for real-time feeds or sensor networks. AI flags issues by analyzing logs and batch data, making it a practical, scalable solution for warehouses of any size.

Crystal Ball Labor: How AI Predicts Warehouse Workforce Needs

When people think of AI in warehouse management, they often picture robots zipping around. But the real magic—especially for non-automated warehouses—happens quietly in the background. AI-powered workforce optimization uses historical order data and transactional volumes from your WMS or ERP to forecast labor needs with surprising accuracy. This means no more guesswork or chronic overtime. Overstaffing becomes a thing of the past, and shift optimization is finally within reach.

I’ve seen this transformation firsthand. Once, I watched a warehouse where labor schedules were always in chaos—overtime was the norm, and temp staff were constantly called in at the last minute. Then, AI-driven labor planning entered the scene. Schedules were reshuffled based on real demand forecasts, and suddenly, workflows smoothed out. Chronic overtime faded, and the team felt less burnt out. It was a subtle but powerful shift—one that didn’t require a single robot or conveyor belt upgrade.

Labor is often the single largest operating expense in warehouse management. AI can optimize shift scheduling down to the hour, ensuring that you only have as many people on the floor as you actually need. This is especially valuable during peak seasons, when demand spikes can otherwise lead to staffing panics or costly misallocations. Research shows that AI-based labor planning can contribute to logistics cost reductions of up to 15%. For midsize warehouses that can’t justify full automation, this kind of cost savings efficiency is a game changer.

AI-powered inventory management isn’t just about stock levels—it’s about aligning your workforce with actual demand. By leveraging predictive analytics, warehouses can avoid both under- and over-staffing, keeping crews happier and operations lean. As Nina Meyers, HR Lead, puts it:

"Having AI handle workforce planning? It’s like always having a manager who never sleeps."

For cost-conscious operations, workforce optimization AI is quickly becoming essential. The payoff is clear: leaner teams, fewer headaches, and a bottom line that finally gets some breathing room. And all of this is possible without a single robot in sight—just smarter use of your existing data.

Returns & Second Chances: AI Tackles Reverse Logistics with Data (Not Drones)

When I think about warehouse efficiency, reverse logistics often gets overlooked. Yet, returns are a huge cost center—especially in industries with high product churn, like apparel and electronics. That’s where reverse logistics optimization powered by AI comes in, and you don’t need robots or drones to see results.

AI-powered inventory management systems quietly transform how we handle returns. Instead of just reacting to returned items, AI analyzes historical data, sales patterns, and even customer feedback to identify which products are most likely to come back. This isn’t just theory—research shows that AI applications in returns management have led to measurable reductions in return-related costs and product waste.

Let me share a real-world example: A small-parts distributor was struggling with high return rates. By implementing product returns reduction AI, the system flagged a chronic mispick issue that had gone unnoticed for months. Once the root cause was addressed, return rates dropped significantly—no automation required, just smarter use of data.

AI doesn’t stop at flagging problems. It recommends new inventory or shipping strategies to avoid overstocking items that are frequently returned. For instance, if a certain SKU gets sent back due to sizing issues, AI can suggest adjusting order quantities or even changing suppliers. This kind of insight guides smarter replenishment and stock moves, helping warehouses cut losses on returns without expensive automation.

What’s especially powerful is how AI can analyze reasons for returns at scale. It sifts through return codes, customer comments, and transaction logs to spot patterns that humans might miss. This allows for continuous improvement—stocking smarter, not just handling returns faster.

As Leandro Batista, a Returns Manager, puts it:

'Reverse logistics is a puzzle—AI is the piece that makes the rest fit.'

Ultimately, non-automated warehouse AI solutions empower teams to lower the hidden costs of returns through prevention, not just processing. By tracking high return-rate items and pinpointing the “why” behind each return, AI shapes future stocking and process decisions—reducing both cost and waste, all without a single robot in sight.

Rinse and Repeat: AI-Based Continuous Process Optimization Without Robots

When most people think of AI in the warehouse, they picture robots zipping around or sensors tracking every movement. But in reality, AI-powered inventory management can quietly transform even the most manual, non-automated warehouses—no robots required. The secret? Reinforcement learning.

Reinforcement learning models in AI are designed to simulate and improve warehouse routines using only the data you already have. There’s no need for a tech overhaul or expensive hardware. Instead, the AI reviews historical records—like picking times, order accuracy, and route efficiency—and suggests small tweaks. Maybe it’s a new picking route, a minor adjustment to the layout, or a change in workflow. These suggestions come purely from observing outcomes and learning what works best over time.

I’ve seen this firsthand. Our weekly pickers used to complain about one slow aisle that always seemed to bottleneck the process. After running our data through a non-automated warehouse AI solution, the system recommended a simple layout change. We tried it. The result? Each route was 20 minutes faster, and we didn’t have to invest in any new technology.

This is the power of operational improvements AI—it’s not about one big change, but about continuous, incremental progress. Research shows that AI-powered reinforcement learning delivers ongoing process optimization, adapting to real-world outcomes as they happen. The optimization cycle doesn’t stop after the initial setup. As conditions shift—seasonal demand, new staff, or changing product lines—the AI adapts, refining its recommendations and keeping improvements coming.

Reinforcement learning is the backbone of continuous improvement in AI-driven warehouses.

AI optimization cycles don’t end—they evolve as your business does.

Every small experiment, every tweak, adds up to significant gains over time.

'Optimization is not a one-time event—it’s a habit powered by AI.' – Carla Jensen, Process Improvement Lead

Even in manual environments, this iterative approach means you can see real, measurable benefits—faster picking, fewer errors, and smarter workflows. No robots, just better decisions, made possible by reinforcement learning and AI-powered inventory management.

Conclusion: No Robots, No Problem—Why AI’s Best Moves Are (Still) Invisible

When we talk about operational improvements with AI, it’s easy to picture high-tech robots gliding through spotless warehouses. But the real story is much quieter—and far more accessible. Modern AI pulls big wins from legacy systems, working behind the scenes with the data you already have. There’s no need for expensive robotics or smart sensors. In fact, research shows that most operational benefits of AI are available regardless of your warehouse’s tech maturity.

From cardboard chaos to clean-room precision, every warehouse can see tangible gains by using smarter data. AI-powered inventory management isn’t just about automation; it’s about making better decisions. Whether you’re optimizing inventory, forecasting demand, or improving slotting strategies, AI can help you move from reactive to proactive—without any new hardware. Studies indicate that AI demand forecasting reduces errors by up to 50% and improves inventory optimization by as much as 15%. These are results that matter, especially when labor and logistics costs are on the line.

What’s most exciting is how AI democratizes efficiency. You don’t have to despair over a lack of bots or sensors. Instead, experiment, iterate, and stay curious. Even a simple spreadsheet can become a powerful tool when paired with the right AI algorithms. As more warehouses adopt these solutions, the partnership between human expertise and AI insights is quietly driving the future of supply chain management.

Imagine a Monday morning when your warehouse runs smoother than a robot-run Amazon facility—all because your old spreadsheet and new AI quietly shook hands over the weekend. That’s not science fiction; it’s the reality for warehouses that embrace AI-powered inventory management and demand forecasting today. As Marcelo Gutierrez, a supply chain strategist, puts it:

"The best kind of AI in warehousing is the kind nobody notices—just improved results."

So, whether you’re running a traditional warehouse or just starting to explore operational improvements with AI, remember: you don’t need robots to see exponential gains. Sometimes, the most powerful moves are the ones you never see coming.