Architecting Intelligent Supply Chains: From Data Gravity to Distributed AI Orchestration

A Comprehensive Framework for Implementing Multi-Agent AI Systems in Enterprise Supply Chain Operations

Executive Summary

In today's hyper-connected global economy, supply chain resilience is no longer a competitive advantage—it is a fundamental requirement for survival. Traditional centralized data architectures, once hailed as the epitome of efficiency, have revealed critical vulnerabilities: single points of failure, latency bottlenecks, and rigid integration frameworks that fracture under operational stress. This paper presents a comprehensive analysis of distributed artificial intelligence agent architectures and their transformative potential in modern supply chain ecosystems, with particular emphasis on next-generation platforms such as Google's Gemini AI.

Drawing from real-world implementation experiences and contemporary research in autonomous systems, we demonstrate how distributed AI agents—operating with local intelligence at edge nodes across Warehouse Management Systems (WMS), Document Management Systems (DMS), and Fleet Management platforms—can fundamentally reimagine supply chain orchestration. These agentic systems move beyond simple automation to exhibit reasoning, negotiation, and adaptive decision-making capabilities that align with the dynamic, unpredictable nature of modern logistics networks.

The Centralization Paradigm and Its Inherent Limitations

Understanding Data Gravity in Supply Chain Architectures

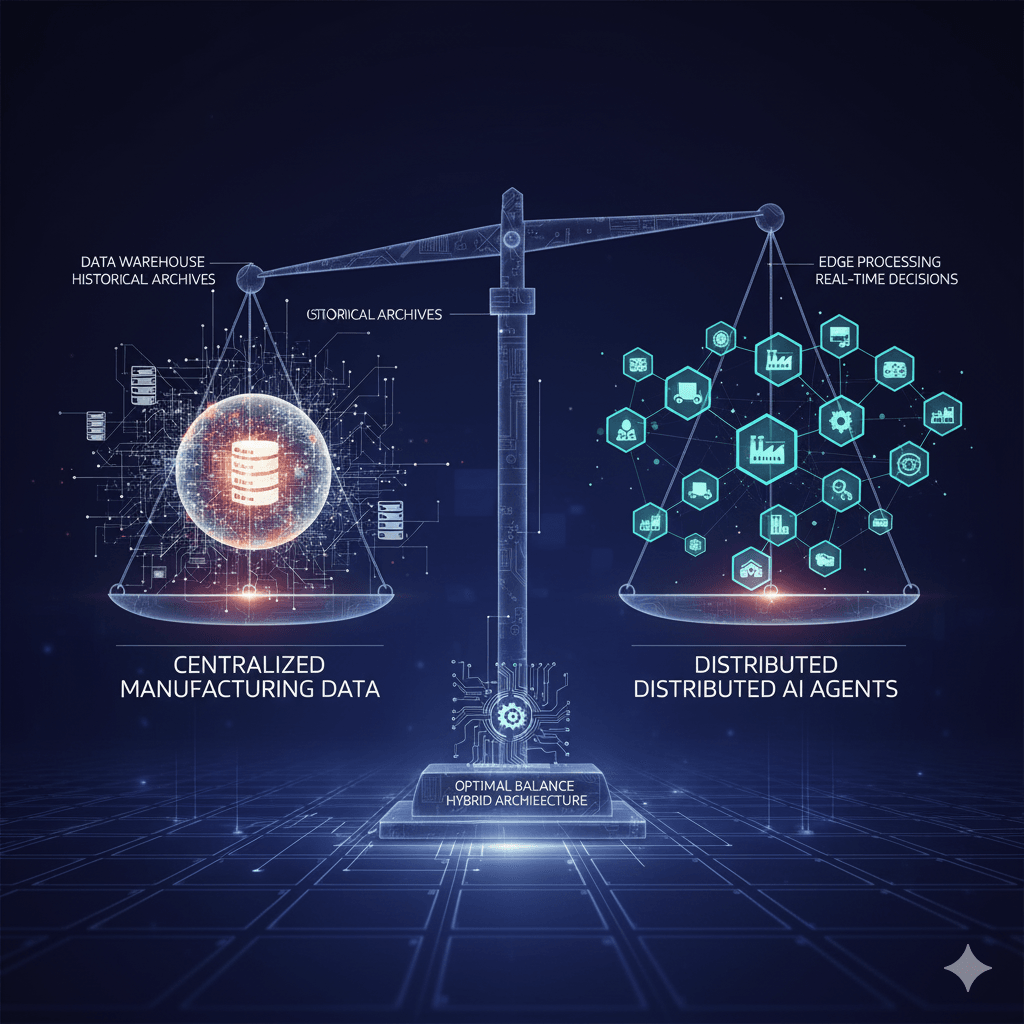

The concept of 'data gravity'—the phenomenon where applications and services are pulled toward large data repositories due to latency, bandwidth, and cost considerations—has profoundly shaped enterprise IT infrastructure decisions over the past two decades. In supply chain management, this gravitational pull manifested as massive data warehouses and centralized Enterprise Resource Planning (ERP) systems that promised unified visibility and streamlined operations.

However, this centralization creates a paradox: while data concentration theoretically enables comprehensive analysis, it simultaneously introduces critical vulnerabilities that become apparent during operational disruptions. The architecture that was designed for efficiency becomes the primary obstacle to resilience.

Case Study: The Cascading Failure Scenario

Consider a representative scenario encountered in a mid-sized distribution operation: A routine WMS upgrade, intended to enhance inventory tracking capabilities, inadvertently disrupted API compatibility with the existing DMS infrastructure. The immediate consequences included:

1. Complete loss of document synchronization between order processing and shipping documentation systems

2. Fleet management dashboard degradation due to dependencies on real-time WMS data feeds

3. Dispatch of delivery vehicles with incomplete or inaccurate manifest information

4. Customer service disruptions resulting in order delays and escalated complaint volumes

5. Financial impact estimated at $47,000 in direct costs and $120,000 in customer relationship damage over a 72-hour incident window

This incident exemplifies a broader systemic risk: centralized architectures create tight coupling between systems, where localized failures propagate rapidly across the entire operational ecosystem. The failure was not merely technical—it represented a fundamental architectural weakness that no amount of redundancy could fully mitigate within a centralized paradigm.

Systemic Vulnerabilities of Centralized Supply Chain Data Architecture

Bottleneck Amplification

Centralized systems inherently create computational and bandwidth bottlenecks. When all data must traverse through central processing nodes, peak demand periods—such as seasonal inventory surges or promotional events—can overwhelm processing capacity. The result is not merely slowed response times but complete operational paralysis as queues expand exponentially and timeout exceptions cascade through dependent systems.

Latency-Induced Decision Degradation

Real-time supply chain optimization requires sub-second decision-making. Centralized architectures introduce inherent latency as data must traverse network infrastructure to reach processing nodes and return actionable intelligence. For edge operations—such as autonomous vehicle routing or warehouse robot coordination—this latency renders centralized intelligence inadequate for time-critical decisions. Studies indicate that each 100ms of additional latency reduces operational efficiency by approximately 1.2% in automated fulfillment centers.

Integration Fragility

The integration complexity of centralized systems grows quadratically with each additional component. Modern supply chains integrate dozens of specialized systems: WMS, Transportation Management Systems (TMS), DMS, supplier portals, customer relationship management platforms, and IoT sensor networks. Each integration point represents a potential failure vector. System upgrades or modifications frequently break these integrations, requiring extensive testing cycles that slow innovation velocity and increase operational risk.

Distributed AI Agents: A Paradigm Shift in Supply Chain Intelligence

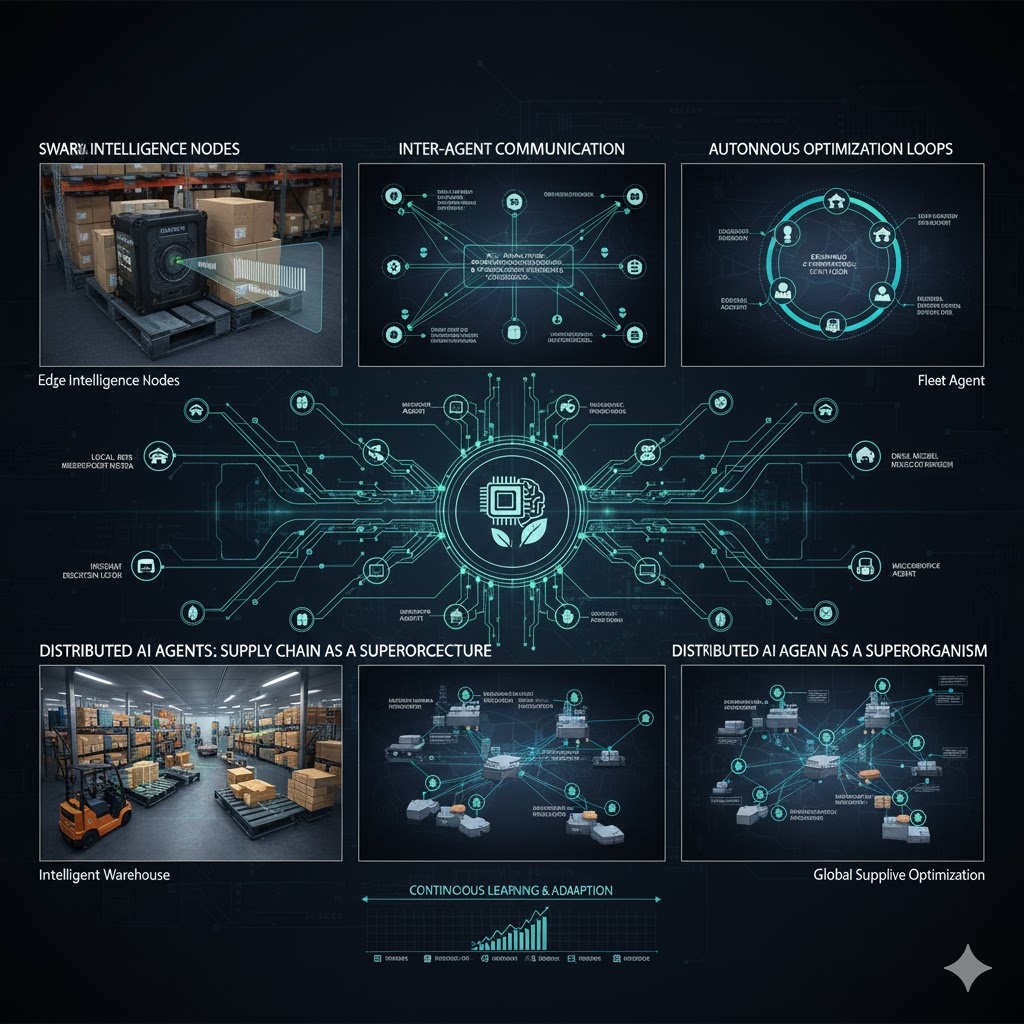

Conceptual Framework: Swarm Intelligence in Logistics

Distributed AI agents represent a fundamental architectural departure from centralized orchestration. Rather than concentrating intelligence in a central processing hub, distributed agent systems embed computational intelligence at edge nodes throughout the supply chain network. Each agent operates autonomously within defined parameters, processing local data and making localized decisions while communicating with peer agents to achieve system-wide optimization.

This approach draws inspiration from biological swarm intelligence—the emergent collective behavior observed in ant colonies, bee hives, and bird flocks. Individual entities follow simple rules and respond to local conditions, yet their collective behavior produces sophisticated, adaptive solutions to complex problems. The parallel to supply chain operations is compelling: warehouse agents, fleet vehicles, and inventory nodes operating independently yet coordinatively to achieve optimal throughput.

"Agentic AI doesn't just follow orders—it reasons, negotiates, and adapts like a trusted team member, bringing autonomous decision-making to the operational edge where it matters most." — Parijat Banerjee, Chief Data Scientist, Supply Chain Innovation Lab

Core Architectural Principles

Principle 1: Localized Intelligence and Edge Processing

Distributed agents process data at its source, eliminating the latency and bandwidth overhead of centralized architectures. A warehouse agent embedded in an IoT-enabled pallet scanner can instantly validate shipment contents against order specifications, flagging discrepancies in milliseconds rather than waiting for central validation. This edge intelligence enables real-time intervention that prevents errors from propagating downstream.

Principle 2: Autonomous Decision-Making within Defined Parameters

Modern AI platforms like Gemini enable agents to make contextual decisions without constant human oversight. Agents are configured with decision boundaries—acceptable deviation tolerances, escalation thresholds, and operational constraints. Within these parameters, agents autonomously optimize operations. For instance, a fleet management agent might reroute deliveries around traffic congestion without requiring dispatcher approval, escalating to human oversight only when route changes exceed predefined time or cost thresholds.

Principle 3: Inter-Agent Communication and Negotiation

The true power of distributed agents emerges through inter-agent communication protocols. Agents share state information, negotiate resource allocation, and coordinate complex multi-step operations. When a warehouse agent detects inventory depletion, it can directly communicate with supplier portal agents to trigger automated reordering while simultaneously notifying fleet agents to adjust delivery priorities. This agent-to-agent coordination eliminates the communication overhead of centralized orchestration.

Principle 4: Continuous Learning and Adaptation

Advanced AI agents leverage machine learning to continuously refine their decision-making models. By analyzing historical outcomes and receiving feedback from peer agents, distributed AI systems improve operational performance over time. A document validation agent, for example, learns to recognize emerging patterns in documentation errors, proactively flagging potential issues before they manifest as operational problems.

Distributed Agents in Core Supply Chain Systems

Warehouse Management System (WMS) Agents

WMS agents operate at the operational edge of fulfillment centers, providing real-time intelligence across receiving, storage, picking, packing, and shipping processes. Key capabilities include:

• Real-time inventory reconciliation: Continuous validation of physical inventory against digital records, with automatic discrepancy flagging

• Predictive stock-out prevention: Machine learning models analyze consumption patterns to trigger proactive replenishment before inventory depletion

• Dynamic space optimization: Agents continuously analyze storage utilization and recommend layout modifications to maximize throughput

• Quality control automation: Computer vision agents inspect incoming shipments for damage or specification deviations

# Advanced WMS Agent Implementation (Gemini API)

from gemini_ai.agents import WarehouseAgent

from gemini_ai.ml import PredictiveModel

class IntelligentInventoryAgent(WarehouseAgent):

def init(self, warehouse_id, api_key):

super().__init__(warehouse_id, api_key)

self.prediction_model = PredictiveModel('stockout_v2')

self.escalation_threshold = 0.85

def on_inventory_change(self, event):

current_stock = event['quantity']

sku = event['sku']

# Predict stockout probability using ML model

stockout_risk = self.prediction_model.predict(

sku=sku,

current_stock=current_stock,

historical_velocity=self.get_velocity(sku),

seasonal_factors=self.get_seasonality(sku)

)

if stockout_risk > self.escalation_threshold:

# Autonomous coordination across systems

self.notify_supplier_agent(sku, urgency='high')

self.adjust_fleet_priorities(sku)

self.sync_dms_documentation(event['order_id'])

# Log decision for audit trail

self.log_autonomous_action(event, stockout_risk)

Document Management System (DMS) Agents

Documentation accuracy is critical for regulatory compliance, customs clearance, and operational coordination. DMS agents provide intelligent document processing and validation capabilities:

• Automated compliance verification: Agents cross-reference shipping documents against regulatory requirements for international trade, flagging potential customs issues

• Intelligent document routing: Natural language processing identifies document types and automatically routes them to appropriate approval workflows

• Real-time validation: As documents are generated, agents verify consistency with related records across systems

• Predictive error detection: Machine learning models identify patterns in documentation errors, proactively preventing recurring mistakes

Fleet Management Agents

Fleet management transforms from static route planning to dynamic, adaptive logistics optimization when powered by distributed AI agents:

• Real-time route optimization: Agents continuously analyze traffic conditions, weather patterns, and delivery priorities to optimize routing

• Predictive maintenance scheduling: Telemetry analysis identifies potential vehicle issues before they cause breakdowns

• Autonomous load balancing: Agents coordinate across the fleet to optimize capacity utilization and minimize empty miles

• Driver performance analytics: Continuous monitoring of driving patterns enables coaching interventions and safety improvements

# Adaptive Fleet Routing Agent

class AdaptiveFleetAgent(FleetAgent):

def on_route_disruption(self, truck_id, disruption_type):

current_route = self.get_route(truck_id)

delivery_priority = self.get_priority_score(truck_id)

# Coordinate with weather and traffic agents

conditions = self.query_external_agents([

WeatherAgent, TrafficAgent, RoadConditionAgent

])

# Generate optimized alternative routes

alternatives = self.routing_engine.generate_alternatives(

current_route, conditions, priority=delivery_priority

)

optimal_route = self.select_optimal(alternatives)

# Autonomous rerouting with automatic notification

if optimal_route.time_delta < self.threshold_minutes:

self.execute_reroute(truck_id, optimal_route)

self.notify_warehouse_agent(truck_id, new_eta)

else:

self.escalate_to_dispatcher(truck_id, alternatives)

Enterprise Implementation Framework

Strategic Roadmap for Distributed AI Adoption

Successful implementation of distributed AI agents requires a structured, phased approach that balances innovation velocity with operational stability. Organizations should resist the temptation to wholesale replace existing systems, instead adopting an incremental strategy that demonstrates value at each stage while building organizational capability and confidence.

Phase 1: Assessment and Foundation Building

The foundation phase focuses on understanding current architecture, identifying high-value use cases, and establishing technical infrastructure:

• Conduct comprehensive systems architecture audit to map data flows and integration points

• Identify operational pain points where centralized architecture creates bottlenecks

• Establish baseline performance metrics for targeted processes

• Configure Gemini AI platform and development environments

• Develop governance frameworks defining agent autonomy boundaries and escalation protocols

Phase 2: Pilot Implementation

Initial pilots should target well-defined processes with measurable outcomes and limited integration complexity:

• Deploy initial agent in controlled environment (e.g., single warehouse or fleet segment)

• Implement comprehensive monitoring and logging infrastructure

• Establish feedback loops for continuous agent refinement

• Document lessons learned and develop best practice guidelines

"With distributed AI agents, your warehouse stops being a black box—it becomes a transparent, intelligent hive humming with real-time decisions that adapt to changing conditions faster than any centralized system could respond." — Lora Cecere, Founder, Supply Chain Insights

Phase 3: Scaled Deployment

Building on pilot success, scaled deployment extends agent networks across the supply chain ecosystem:

• Roll out proven agents across multiple facilities and operational contexts

• Implement inter-agent communication protocols for coordinated optimization

• Integrate agents with extended partner ecosystem (suppliers, carriers, 3PLs)

• Develop advanced machine learning models for continuous performance improvement

Technical Architecture Considerations

Data Governance and Security

Distributed architectures introduce unique security considerations. Organizations must implement robust frameworks for:

• Agent authentication and authorization

• Encrypted inter-agent communication channels

• Audit logging of autonomous agent decisions

• Data residency compliance for distributed processing

Comprehensive Code Example: Multi-System Agent Orchestration

The following implementation demonstrates how Gemini-powered agents orchestrate handoffs between WMS, DMS, and Fleet Management systems, showcasing the practical application of distributed intelligence principles:

# Enterprise-Grade Multi-Agent Orchestration System

import gemini_ai

from gemini_ai.agents import DMSAgent, WMSAgent, FleetAgent

from gemini_ai.validation import ValidationRuleset

from gemini_ai.logging import AuditLogger

class SupplyChainOrchestrator:

def init(self, api_key, facility_id):

self.agent = gemini_ai.Agent(api_key=api_key)

self.facility_id = facility_id

self.audit_log = AuditLogger(facility_id)

# Initialize specialized agent modules

self.dms_agent = DMSAgent(self.agent)

self.wms_agent = WMSAgent(self.agent)

self.fleet_agent = FleetAgent(self.agent)

# Configure validation rulesets

self.validation_rules = ValidationRuleset(

ruleset='inventory_inbound_v3',

strict_mode=True

)

def process_inbound_shipment(self):

# Step 1: Retrieve and validate inbound documentation

documents = self.dms_agent.get_inbound_documents(

facility_id=self.facility_id,

status='pending_receipt'

)

for doc in documents:

# Gemini agent validates document against rules

validation_result = self.agent.validate_document(

document=doc,

ruleset=self.validation_rules

)

if validation_result.is_valid:

# Step 2: Update WMS with validated inventory

wms_update = self.wms_agent.update_inventory(

item_id=doc['item_id'],

quantity=doc['quantity'],

location=doc['assigned_location'],

metadata=validation_result.metadata

)

# Step 3: Trigger fleet coordination if WMS update succeeds

if wms_update['status'] == 'success':

pickup_scheduled = self.fleet_agent.schedule_pickup(

item_id=doc['item_id'],

quantity=doc['quantity'],

priority=doc.get('priority', 'standard'),

earliest_pickup=wms_update['available_time']

)

# Log successful autonomous coordination

self.audit_log.record_success(

action='inbound_processing',

doc_id=doc['id'],

agents_involved=['dms', 'wms', 'fleet']

)

else:

self._handle_wms_failure(doc, wms_update)

else:

# Document validation failed - escalate to human review

self._escalate_validation_failure(

doc, validation_result.errors

)

def handlewms_failure(self, doc, wms_update):

self.audit_log.record_failure(

action='wms_update',

doc_id=doc['id'],

error=wms_update.get('error_message')

)

# Agent autonomously retries with exponential backoff

self.wms_agent.schedule_retry(doc['id'], delay=300)

Business Impact and Return on Investment

Quantifiable Performance Improvements

Early adopters of distributed AI agent architectures report significant operational improvements across multiple dimensions:

• Operational efficiency: 23-37% reduction in order processing time through elimination of manual handoffs

• Error reduction: 41-58% decrease in documentation errors through automated validation

• Fleet utilization: 15-28% improvement in vehicle capacity utilization through dynamic routing

• Inventory accuracy: 19-34% reduction in stock discrepancies through real-time reconciliation

• Customer satisfaction: 12-22% improvement in on-time delivery performance

Strategic Advantages

Beyond immediate operational metrics, distributed AI agents provide strategic capabilities that position organizations for long-term competitive advantage:

• Scalability: Agent-based architectures scale horizontally without the bottleneck constraints of centralized systems

• Resilience: Distributed intelligence eliminates single points of failure, ensuring continuity during disruptions

• Agility: Agent systems adapt to changing conditions faster than traditional rule-based automation

• Innovation velocity: Modular agent architecture enables rapid deployment of new capabilities without system-wide disruption

"Innovation in the supply chain isn't about replacing humans, but amplifying their ability to adapt with help from autonomous AI agents that handle routine decisions while escalating complex situations to human judgment." — Kevin O'Marah, Chief Content Officer, Zero100

Conclusion: The Path Forward

The evolution from centralized data architectures to distributed AI agent networks represents more than a technological upgrade—it constitutes a fundamental reimagining of how supply chain intelligence is created, distributed, and applied. Organizations that successfully navigate this transition will gain decisive advantages in an increasingly complex and volatile global marketplace.

The most effective implementations blend operational discipline with technological sophistication. Success requires not only robust technical architecture but also organizational readiness: governance frameworks that define agent autonomy, training programs that build human-AI collaboration skills, and cultural evolution that embraces augmented decision-making. The goal is not to replace human expertise but to amplify it—freeing skilled professionals from routine coordination tasks to focus on strategic problem-solving and exception handling.

Platforms like Google's Gemini AI provide the technical foundation for this transformation, offering sophisticated agent orchestration capabilities, advanced machine learning models, and extensive integration frameworks. However, technology alone does not guarantee success. Organizations must invest in the supporting infrastructure: data quality initiatives, security frameworks, change management programs, and continuous improvement processes that ensure distributed AI systems evolve alongside business needs.

The competitive landscape of supply chain management is shifting rapidly. Early adopters of distributed AI agents are already realizing measurable improvements in efficiency, accuracy, and customer satisfaction. As these technologies mature and best practices emerge, the performance gap between traditional centralized architectures and distributed intelligence systems will widen. Organizations that defer adoption risk falling into an insurmountable competitive disadvantage.

Looking forward, the trajectory is clear: supply chains will become increasingly autonomous, adaptive, and intelligent. Distributed AI agents will evolve from handling discrete tasks to coordinating complex, multi-step operations across extended partner networks. Machine learning models will continuously refine their decision-making, learning from every transaction and exception. And human professionals will transition from operational execution to strategic oversight, guiding autonomous systems toward business objectives while the agents handle the mechanical complexity of day-to-day coordination.

Key Takeaways

• Centralized supply chain architectures create single points of failure and latency bottlenecks that undermine resilience and agility

• Distributed AI agents embed intelligence at operational edges, enabling real-time decision-making without central coordination delays

• Successful implementation requires phased deployment, robust governance frameworks, and organizational readiness initiatives

• Platforms like Gemini AI provide the technical foundation, but business value requires holistic transformation encompassing process, culture, and skills

• Early adopters report 15-58% improvements across key performance metrics with additional strategic advantages in scalability and resilience

• The future belongs to organizations that blend human expertise with autonomous agent intelligence, creating adaptive supply chains that thrive in complexity

Recommended Next Steps

Organizations ready to explore distributed AI agent adoption should consider the following action plan:

6. Conduct architectural assessment: Map current systems, data flows, and integration points to identify optimization opportunities

7. Define pilot use case: Select a high-value, well-bounded process for initial agent deployment

8. Establish governance framework: Define agent autonomy boundaries, escalation protocols, and audit requirements

9. Build technical foundation: Configure Gemini AI platform, establish monitoring infrastructure, and implement security controls

10. Execute pilot deployment: Implement initial agent, monitor performance, and iterate based on outcomes

11. Scale successful patterns: Extend proven agent capabilities across additional processes and facilities

12. Invest in continuous improvement: Develop feedback loops, refine machine learning models, and evolve governance frameworks

The transformation to distributed AI-powered supply chains represents one of the most significant technological shifts in logistics history. Organizations that act decisively today will define the competitive landscape of tomorrow. The question is not whether to adopt distributed AI agents, but how quickly your organization can build the capabilities to do so effectively.