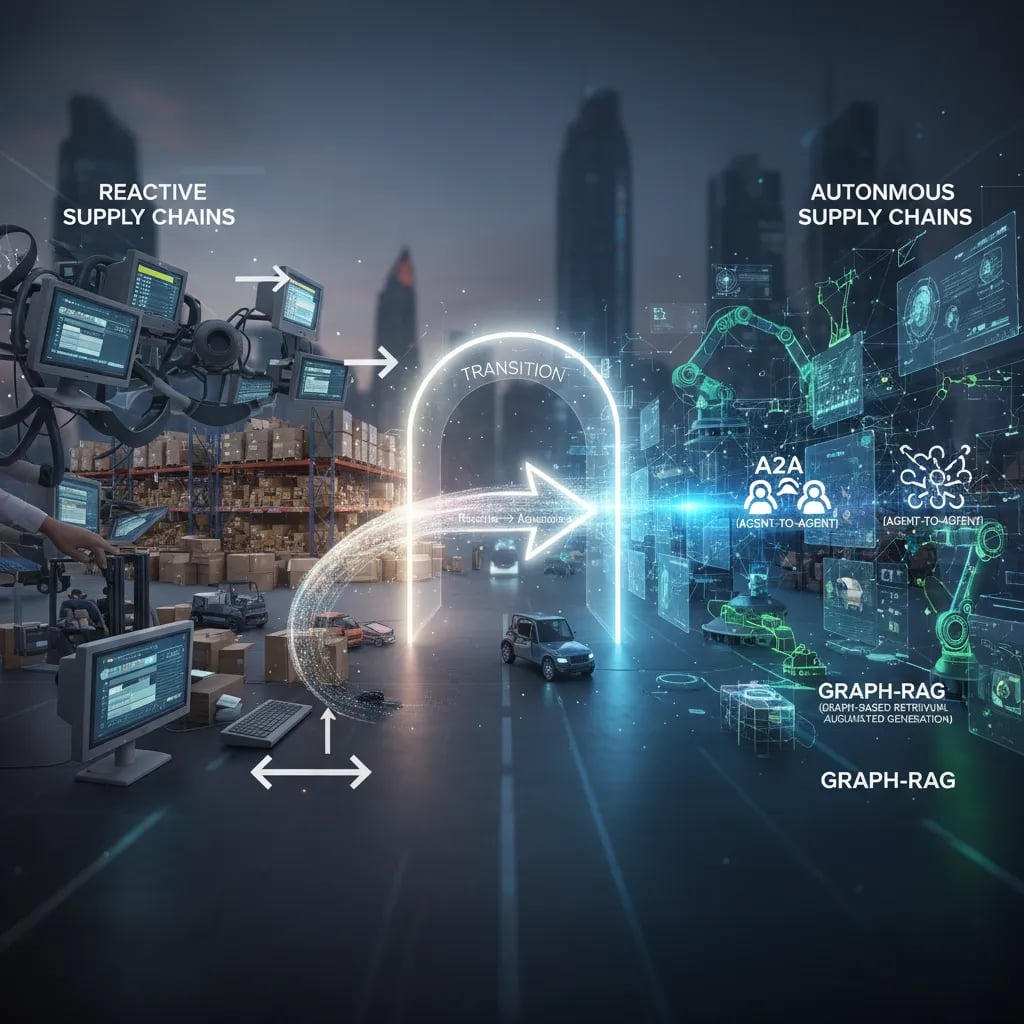

The piece opens by re-examining pandemic-era shocks—COVID-19 as a hard lesson—and maps how brittle, siloed supply chains faltered. It argues that today's volatility demands moving beyond reactive firefighting to proactive and ultimately autonomous supply chains, enabled by Agent-to-Agent (A2A) communication, Model Context Protocol (MCP) and Graph-based Retrieval Augmented Generation (Graph-RAG). The introduction blends a brief anecdote of a fictional regional retailer who lost a season's worth of inventory during the pandemic with hard wake-up statistics, setting a strategic and practical tone.

Why Now? Pandemic Lessons and the Case for Change

COVID-19 made fragility visible

In 2020, a fictional regional retailer in the Midwest planned a strong spring promotion. A key overseas supplier missed ship dates after rolling factory shutdowns, and the retailer’s backup options were already booked. By the time inventory arrived, demand had shifted and the seasonal window was gone. The loss was not just revenue—it was trust, shelf space, and momentum.

That story mirrors what many networks experienced: ripple effects from factory closures, port congestion, driver shortages, and sudden demand swings. Traditional planning cycles and manual escalations reacted too slowly, especially when data was spread across teams and partners.

Visibility is necessary, but not sufficient

Many organizations responded with control towers. When integrated with ERP, WMS, and TMS, control towers expand real-time visibility and support faster coordination. Yet visibility alone does not decide, negotiate, or execute. Without automation, teams still face alert fatigue and late interventions.

AI is shifting from “nice to have” to operational baseline

Early adopters of AI supply chain transformation used machine learning to accelerate S&OP and improve forecast accuracy, tightening cadence from monthly to weekly (or faster) and improving exception detection. This is the practical bridge from reactive firefighting to predictive supply chain management—and a direct driver of supply chain resilience during disruption.

AI will move supply chains from reactive triage to predictive stewardship — Dr. Maria Alvarez, Supply Chain Researcher

Momentum is also financial: by 2026, AI is projected to drive capital investment in 75% of supply chain organizations.

Why autonomy now: three technologies that fit together

A2A enables agents to coordinate actions across nodes in real time.

MCP standardizes secure context sharing across systems and partners.

Graph-RAG connects events to dependencies, exposing cascading risk paths.

Together, they turn digital transformation into decisions and execution—not just dashboards.

The High Cost of Reactive Supply Chains

In many organizations, supply chain management still runs on a reactive loop: a problem appears, teams scramble, and decisions are made with partial data. Slow response times and siloed systems reduce real-time visibility, so issues like inventory stockouts and supplier delays are detected late—often after customers feel the impact.

These failures are expensive in ways that compound. Stockouts create missed sales and customer churn. Delays trigger expedite fees, production downtime, and strained vendor relationships. Forecast errors ripple across multi-tier networks, where one late component can stall an entire build. Human planners cannot continuously track every constraint, exception, and dependency across suppliers, carriers, plants, and DCs—especially when updates arrive in different formats and tools.

Reactive processes cost more than immediate fixes; they erode customer trust over time — James Patel, Operations Director

One manufacturing plant faced a supplier delay and manually rerouted inbound freight through alternate ports. With email-based coordination and no shared context, lead times doubled and planners spent days reconciling updates.

Immediate low-cost fixes (before autonomy)

Consolidate key data feeds to improve real-time visibility across orders, inventory, and transport.

Deploy AI-driven exception detection for forecast outliers and late-ship signals, with replenishment triggers for inventory optimization.

Standardize alerts and ownership so exceptions close fast—critical as 2026 warehouses rely more on robotics and automation for precision and speed.

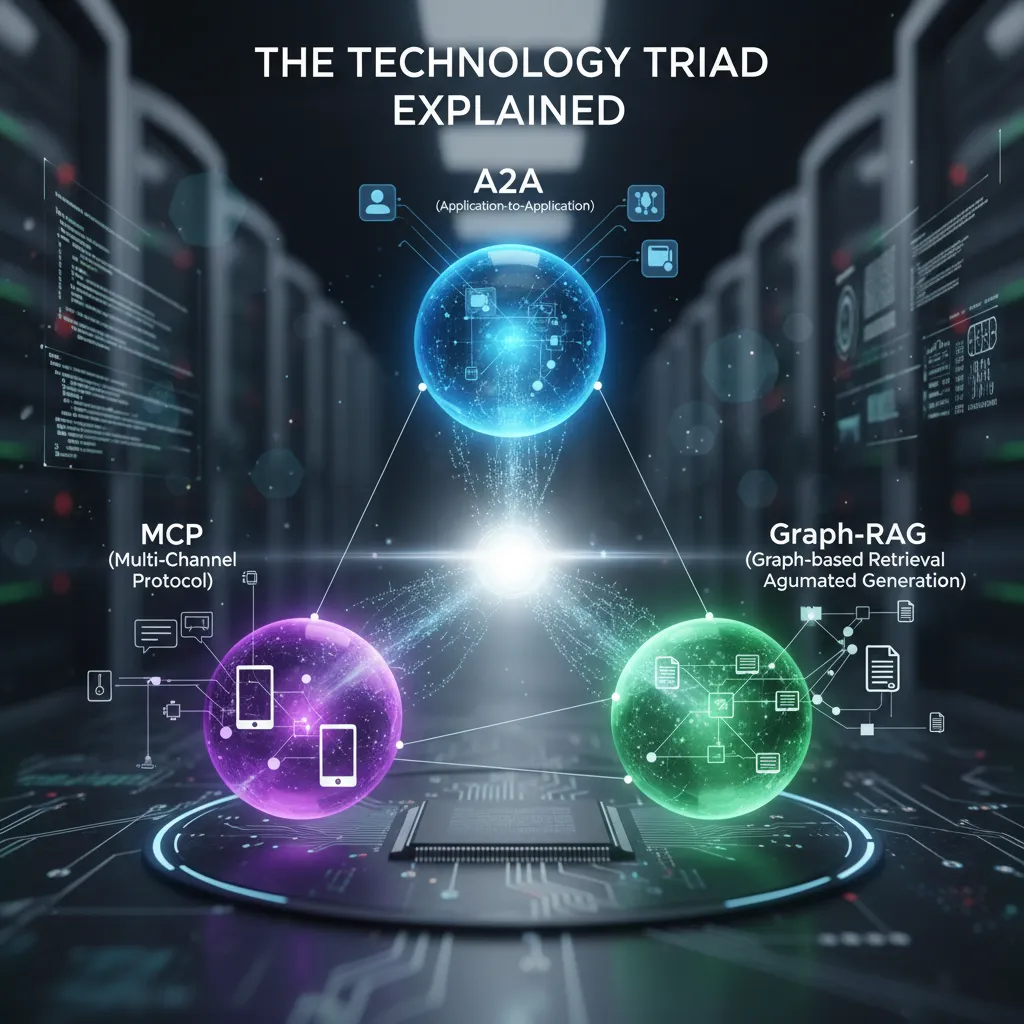

The Technology Triad Explained: A2A, MCP and Graph-RAG

Autonomous supply chains rely on a practical technology triad: Agent-to-Agent communication, the Model Context Protocol, and Graph-RAG. Together, they turn Agentic AI from a single “smart tool” into a coordinated system that can sense, decide, and act across the network.

Agent-to-Agent communication (A2A): distributed negotiation in real time

In A2A, autonomous agents represent supply chain entities—warehouses, carriers, factories, and suppliers—and coordinate directly. Instead of waiting for a central team to reconcile updates, agents negotiate constraints and trade-offs as conditions change, reducing bottlenecks.

A warehouse agent proposes load consolidation based on dock capacity and pick waves.

A transportation agent counters with carrier availability and route cost, then confirms a new plan.

This is where emergent behavior appears: many small, local decisions add up to faster network-wide response. Research signals that by 2027, 40% of operational data will integrate autonomously via AI agents, accelerating this shift.

Model Context Protocol (MCP): a secure “universal translator” for context

MCP enables context-rich sharing across organizational boundaries with privacy controls and dynamic context switching. A retailer’s forecasting AI can share SKU-level demand signals and promotion context with a manufacturer’s production AI—without exposing unrelated sensitive data.

MCP is the bridge that lets disparate AI systems speak and trust each other — Anika Rao, Head of AI Integration

Graph-RAG: relationship-aware reasoning beyond vector search

Unlike vector DB-based RAG that retrieves “similar” text, Graph-RAG models the supply chain as a graph of nodes and links (sites, parts, lanes, suppliers). This makes dependencies explicit and traceable. For example, Graph-RAG can follow a drought event across supplier tiers to reveal risk cascades and impacted SKUs.

Viewed as a living organism: agents are the cells communicating, MCP is the nervous system sharing trusted context, and Graph-RAG is the map that shows how everything connects.

Autonomous Resilience: How Networks Learn and Self-Heal

Autonomous resilience emerges when predictive AI, Agent-to-Agent coordination, and Graph-RAG combine to turn real-time visibility into action. Instead of waiting for a late shipment or a stockout to appear in a dashboard, the network continuously monitors weak signals—carrier dwell time drift, rising temperature variance, supplier lead-time noise—and flags risk before it becomes a crisis. As capital investment shifts, many supply chain organizations are prioritizing AI; by 2026, AI will drive capital investment decisions across the function, and agentic AI is already applied in demand planning and decision-making.

Incident lifecycle: detect → remediate → learn

Detection: Graph-RAG links events to dependencies, creating shared context for agents.

Autonomous remediation: Agents negotiate contingencies—dynamic rerouting, automatic consolidation, and contingency activation—supporting autonomous operations without human intervention.

Post-event learning: Outcomes are captured for AI recalibration, improving future scheduling and decision quality under governance controls.

When agents share context and act, the network becomes its own teacher — Dr. Lena Moretti, Industrial AI Strategist

Sidebar: cold-chain self-heal (pharma)

A pallet sensor detects a temperature anomaly. The logistics agent verifies lane risk, the compliance agent prepares required documentation, and the transport agent reroutes to a validated carrier—while Graph-RAG records the full chain of evidence. This reduces downtime and protects margins. Industry insights suggest that by 2026, over 40% of manufacturers will upgrade production scheduling with AI-driven autonomous capabilities, and 91% of mid-market manufacturers use generative AI in some capacity.

Industry Use Cases: From Pharma to E-commerce

Pharmaceuticals: cold-chain integrity with AI in logistics

A vaccine shipment moves through multiple handoffs. IoT sensors flag a temperature drift, and an A2A agent for the carrier negotiates a new lane with a warehouse agent while Graph-RAG checks product, lane, and site constraints. MCP shares only the needed context (batch rules, lane limits) to keep compliance tight. The result is reduced spoilage, faster exception handling, and cleaner audit trails through compliance automation.

AI-enabled supply chains mean fewer surprises and faster fixes—especially in regulated industries — Karen Liu, Head of Logistics, Pharmatech

Automotive: JIT coordination and semiconductor risk tracing

An OEM running just-in-time assembly faces a sudden chip allocation cut. Graph-RAG traces dependencies across multi-tier suppliers to identify which trims and plants are exposed, not just which Tier 1 is late. A2A agents then coordinate alternate sourcing, transport capacity, and production sequencing. Many networks also redesign for resilience using nearshoring trends and local manufacturing to shorten lead times and reduce single-region risk.

Retail: demand-driven replenishment and inventory rebalancing

A regional heatwave spikes demand for beverages and fans. Store and DC agents use A2A to request transfers, while Graph-RAG links weather signals to SKU-store history and promotion calendars. AI provides targeted decision support such as replenishment triggers and safety-stock adjustments, improving supply chain optimization with fewer stockouts and less overstock.

E-commerce logistics: last-mile and peak-season surge management

During a holiday surge, order volumes shift by ZIP code. A2A agents rebalance labor, slotting, and carrier pickups across nodes, while MCP enables secure context sharing between 3PLs and marketplaces. Graph-RAG helps choose delivery promises based on route constraints and warehouse capacity. Outcomes include faster order fulfillment, higher on-time delivery, and smoother warehouse automation under peak load.

Challenges, Trust and Governance: What Stands in the Way

Trust, transparency, and auditable autonomy

As A2A agents and Graph-RAG begin to recommend actions, leaders must be able to answer a simple question: why did the system decide that? Trust depends on decisions being explainable, auditable, and tied to approved policies—especially for high-impact moves like supplier switches, allocation changes, or expedited freight.

Governance wins trust; without it, autonomy becomes risky — Samuel Okoye, Chief Security Officer

Mitigation often starts with phased rollouts and human-in-the-loop controls for high-risk decisions, while lower-risk tasks (status updates, exception triage) move faster toward automation.

Data governance and privacy in MCP context sharing

MCP can unlock cross-company context, but it also raises data governance questions: what data is shared, at what granularity, and under which rules? Sensitive commercial data (pricing, capacity, customer commitments) must be protected while still enabling useful signals for predictive supply chain management. Clear data contracts, role-based access, and retention rules become core to digital transformation, not paperwork.

Security risks and legacy integration complexity

Autonomous supply chain designs must connect to ERPs, WMS, and TMS platforms that were not built for agent negotiation or continuous reasoning. Integration gaps, identity sprawl, and inconsistent master data can create security and reliability risks. Strong access controls, segmentation, and monitoring should be treated as baseline requirements, aligned with current AI trends in enterprise security.

People, culture, and workforce upskilling

By 2026, supply chain management is increasingly linked with AI, with emphasis on workforce upskilling and governance. Teams need training to supervise agents, validate Graph-RAG outputs, and manage exceptions. ROI timelines are also evolving; many organizations must recalibrate expectations because returns may lag early investments.

Security & governance readiness checklist

Data contracts defined for MCP exchanges (scope, purpose, retention)

Role-based access and least-privilege permissions for agents

Audit logs for decisions, prompts, and retrieved graph evidence

Human approval gates for high-risk actions

Legacy integration testing for ERP/WMS/TMS failure modes

A Pragmatic Roadmap: From Assessment to Optimization

“Start with small, measurable pilots; scale only after clear gains.” — Elena Garcia, VP Supply Chain Transformation

Phase 1 — Assessment (Technology transformation baseline)

Teams begin by mapping data readiness across ERP, WMS, TMS, and supplier feeds, then selecting high-frequency, low-risk decisions for early automation (e.g., reorder exceptions, appointment scheduling). Clear KPIs anchor the effort: forecast accuracy, exception rate reduction, lead-time variability, and cost-to-serve. Governance checkpoints should confirm data access, security, and decision rights before any agent acts.

Phase 2 — Pilot Implementation (Predictive AI + A2A)

Run a focused 8–12 week pilot with a tight scope and measurable outcomes. A common pattern pairs Graph-RAG for knowledge enhancement (policies, supplier constraints, lane history) with Agent-to-Agent (A2A) communication between warehouse and carrier agents to reduce manual coordination. This is where predictive AI proves value by flagging risks early and recommending actions operators can approve.

Phase 3 — Expand & Scale (MCP + network redesign)

After repeatable wins, deploy Model Context Protocol (MCP) for secure context sharing across partners and business units. Add more use cases—autonomous scheduling, dynamic inventory rebalancing, and transportation consolidation—while building feedback loops that capture outcomes and retrain policies. This aligns with research that by 2027, 40% of operational data will integrate autonomously via AI agents.

Phase 4 — Optimization (Autonomous scheduling at scale)

Continuous improvement expands autonomy, strengthens controls, and invests in skills (ops, IT, data, risk). By 2026, over 40% of manufacturers will upgrade production scheduling with AI-driven autonomous capabilities, making governance and monitoring non-negotiable.

Wild Cards: Thought Experiments and Unexpected Angles

A hurricane, a port, and a network that can “think”

Imagine a hurricane shuts down a key port for ten days. In a reactive model, teams scramble, control towers light up, and decision support arrives late—after containers are already stuck. In an autonomous supply chain, Graph-RAG (Graph-based Retrieval Augmented Generation) maps the disruption across lanes, SKUs, contracts, and tier-2 dependencies, then surfaces viable alternates: a secondary supplier with available capacity, a different port with rail access, and a packaging constraint that would have been missed in a spreadsheet.

Next, Agent-to-Agent (A2A) communication kicks in. Procurement agents resequence POs, transportation agents rebid capacity, and warehouse agents adjust inbound appointments. The point is not “automation for its own sake.” In the Age of AI, AI provides decision support that is faster, more consistent, and easier to audit—especially when governance rules and ethical constraints are explicit (e.g., no risky supplier substitutions without compliance checks).

Ecosystems are messy—and that is the lesson

Supply chains behave like ecosystems: sometimes messy, sometimes brilliant. Emergent intelligence can look like chaos until it stabilizes into a new pattern. That is where supply chain innovation gets real—less “perfect plan,” more “adaptive network.”

One imperfect aside: a regional ops manager once dismissed autonomous workflows as “AI theater.” After a small pilot reduced expedite spend and improved ETA accuracy, the same manager became the loudest advocate. Not because the system replaced people, but because it gave them better options under pressure.

Imagination helps companies see not just what is broken, but what could be built — Priya Menon, Strategic Consultant

What “what-if” scenario would stress-test your network most: a port closure, a cyber event, or a sudden demand spike? And if your control towers could recommend actions, who should be accountable for approving them—and why?