A procurement director at a mid-sized food manufacturer watched a week of spoiled inventory evaporate into a mandate: invest in visibility or accept repeated losses. That moment — personal, avoidable and now common — captures why 2026 is framed as a turning point. Between the digital acceleration of 2020–2025 and fresh regulatory and climate pressures, technologies once optional now determine who survives and who leads.

Brainstorm: 5 Distinct Lenses on 2026

Supply Chain Trends 2026 are best viewed through decision lenses, not a long checklist. After the 2020–2025 Acceleration of Technology, 2026 becomes a convergence year—multiple tools connect into real operating systems. These five lenses support Supply Chain Digital Transformation roadmapping and prioritization workshops.

Dr. Laura Chen, Supply Chain AI Lead, Global Logistics Institute: "Seeing technology through multiple lenses helps organizations pick wins that compound over time."

1) Autonomy & intelligence

Generative AI, agentic systems, and control towers shift teams from monitoring to managing exceptions.

Quick wins: AI copilots for planning, automated scenario generation, better forecasting.

Strategic bets: autonomous decision loops for procurement, inventory, and routing.

2) Physical automation

Robotics, AMRs, drones, and warehouse automation address labor gaps and throughput limits.

Quick wins: pick-assist cobots, automated cycle counts, RPA for repetitive tasks.

Strategic bets: autonomous yards, self-driving linehaul pilots, lights-out zones.

3) Trust & traceability

Blockchain and secure multi-party workflows improve provenance, compliance, and dispute resolution.

Quick wins: targeted traceability for high-risk SKUs and regulated lanes.

Strategic bets: smart contracts and consortium-led data standards.

4) Visibility & simulation

IoT, 5G, edge computing, and digital twins turn real-time data into testable decisions.

Quick wins: cold-chain monitoring, predictive maintenance, live ETA accuracy.

Strategic bets: end-to-end network digital twins for disruption modeling.

5) Sustainability & resilience

Carbon tracking, circular systems, cybersecurity, and early quantum readiness protect continuity and compliance.

Quick wins: emissions baselines, route optimization, zero-trust upgrades.

Strategic bets: circular reverse logistics platforms and quantum pilots for optimization.

Generative AI & Autonomous Decision-Making (AI Essential Not Optional)

In 2026, Artificial Intelligence Supply Chain programs move beyond dashboards and alerts. The shift is from predictive models to agentic systems that can generate scenarios, recommend mitigation, and execute routine decisions across planning and execution. This is where Generative AI Planning changes the pace of S&OP: it can draft plans, explain trade-offs, and even forecast new product launches with limited history by blending internal signals with market and external data.

From insights to action: Agentic AI Logistics at scale

Mature deployments report AI Demand Forecasting accuracy of 95%+, while AI agents handle automated procurement negotiations, dynamic inventory positioning, and route re-optimization in near real time. Large logistics providers already run thousands of low-risk transactions through Agentic AI Logistics, freeing teams to focus on exceptions and supplier strategy.

Control towers become decision engines

Control Towers Decision Making is evolving from “see and notify” to “simulate and decide.” Generative models run continuous what-if scenarios (port delays, supplier failures, weather shocks) and propose actions with cost and service impact, making control towers proactive rather than reactive.

Marcus Alvarez, VP Digital Supply Chain, NorthStar Logistics: “Generative AI is the difference between reacting to disruptions and anticipating them — but it starts with trustworthy data.”

What blocks ROI (and how to start)

Data foundations determine achievable forecast accuracy and agent reliability.

Integration, change management, and human oversight remain critical for edge cases.

Pilot generative models on S&OP tasks; measure cycle-time reduction and forecast lift.

Deploy agents gradually in high-frequency workflows (replenishment, routing, order promises).

Use clear KPIs and audit trails to close the gap between adoption and measurable returns.

Robotics, AMRs, Drones & Warehouse Automation Systems

In 2026, Warehouse Automation Systems are moving from “pilot projects” to daily operations. Cobots and autonomous mobile robots (AMRs) now support picking, put-away, and cycle counting, improving throughput while reducing strain and incidents. This is a clear example of how Automation Empowers Workforce: robots handle heavy, repetitive movement, while people focus on exceptions, quality checks, and process improvement.

Where automation is delivering value now

Cobots + AMRs increase pick speed and accuracy, and improve safety in high-traffic aisles.

Drones accelerate inventory visibility in large sites and yards, especially for hard-to-reach locations.

RPA reduces repetitive back-office work (appointments, ASN matching, claims), freeing teams for higher-value tasks.

Automation also supports faster replenishment, which strengthens AI-driven planning and helps lower stockouts and overstock.

Adoption is rising: 61% of logistics providers are adopting digital tracking technologies, and about 49% have integrated warehouse automation.

Anika Patel, Head of Warehouse Ops, Meridian Foods: “After our AMR pilot, throughput improved and staff were happier — machines did the heavy lifting, people did the thinking.”

Last-mile Delivery Solutions and autonomous transport

Drones and autonomous vehicles are expanding Last-mile Delivery Solutions, while self-driving trucks are expected to reach more mainstream use in select corridors by 2026. Many programs also pair autonomy with Transportation Route Optimization to reduce empty miles and improve service levels.

Barriers and a practical rollout path

Robotics adoption can deliver medium-term cost savings, but it requires upfront investment and change programs. The most common scaling bottleneck is integration with WMS and warehouse controls.

Start with cobot-assisted pick-and-pack pilots.

Scale to AMR fleets with clear safety and training plans.

Integrate WMS/TMS early to avoid “islands of automation.”

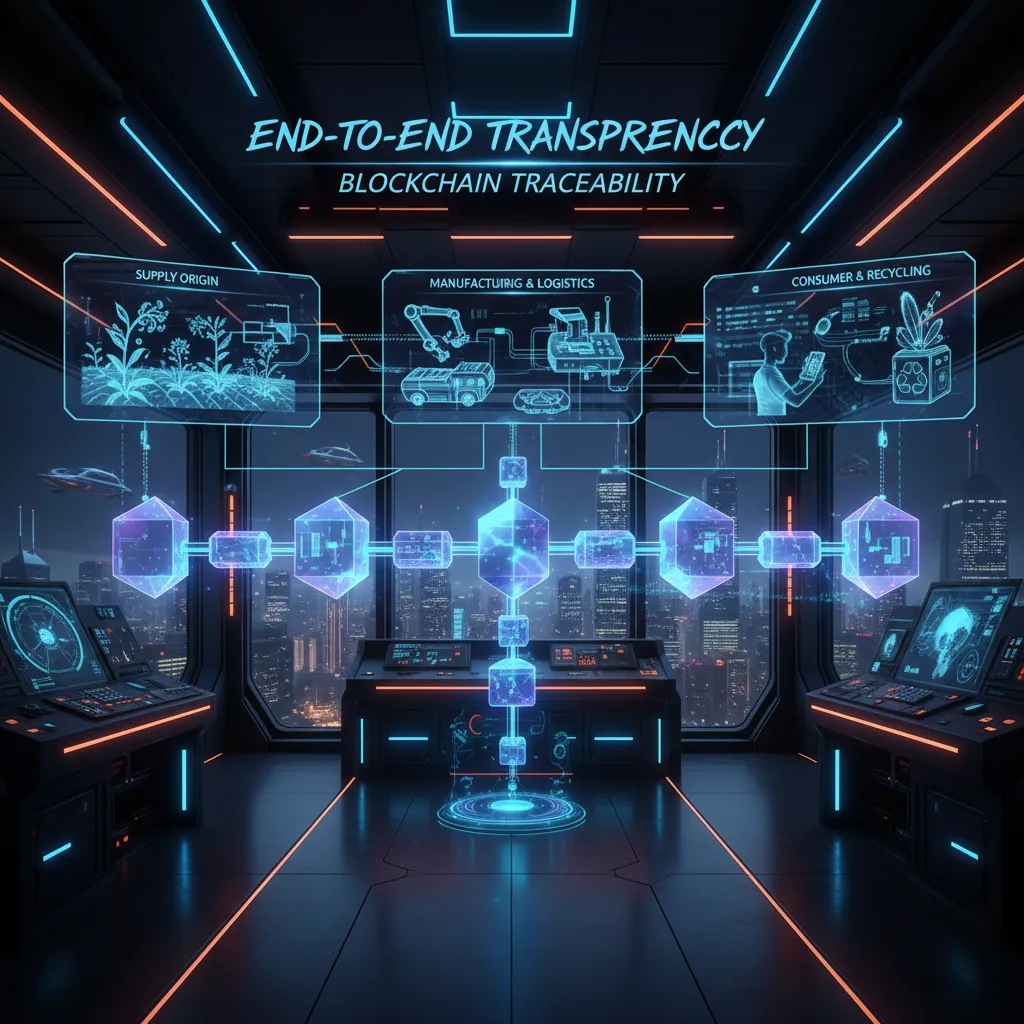

Blockchain Traceability & End-to-End Transparency

From pilots to practical Trust and Traceability

By 2026, blockchain is moving past hype and into day-to-day operations where partners need shared facts. In a Blockchain Traceability Supply Chain model, each handoff can be recorded on a common ledger, helping teams verify provenance, reduce disputes, and simplify cross-border documentation. Smart contracts also support Compliance Automation by triggering checks, approvals, and audit-ready records with far less manual work.

Sofia Martinez, Director of Traceability, FairSource Alliance: "Blockchain creates a common ledger where partners can reconcile facts — not finger-pointing."

Where it is working now

Flagship deployments show clear value when the use case is narrow and the data is reliable. Walmart has used blockchain to speed up food tracing, while Maersk’s TradeLens demonstrated how shared logistics data can reduce friction across global trade lanes. Similar patterns are emerging in pharmaceuticals (chain integrity), luxury goods (authentication), and carbon tracking for ESG claims.

Food safety: faster recalls and root-cause tracing

Counterfeit prevention: verified product history and ownership

Carbon tracking: tamper-evident emissions and activity records

Scaling tip: standards, consortiums, and IoT

Not all pilots scale because partners use different systems and data formats. Consortiums and standards are becoming the practical path to broader adoption, sharing infrastructure costs and reducing integration friction. Combining blockchain with IoT multiplies transparency benefits: sensor readings (temperature, location, shock) can be hashed on-chain to create tamper-evident proof that strengthens provenance claims in a Blockchain Traceability Supply Chain.

Hyperconnected IoT, 5G Networks & Digital Twin Technology

Real-time Visibility Supply Chain: sensors + 5G + edge decisions

By 2026, Real-time Visibility Supply Chain programs will rely on ubiquitous IoT signals—temperature, humidity, shock, and location—streamed over expanding 5G coverage. With edge computing, key checks happen close to the asset (truck, pallet, dock door), reducing latency and enabling fast control loops that a cloud-only setup cannot match. This is also accelerating Control Tower Evolution, shifting from “monitoring dashboards” to systems that detect exceptions and trigger actions.

Digital Twin Technology: simulate first, change with confidence

Digital Twin Technology creates a live virtual copy of a warehouse, fleet, or network, synchronized with IoT data. Leaders can run risk-free simulations for network changes, new SKU introductions, capacity shifts, and disruption scenarios—cutting physical testing costs and speeding time-to-market. Combining IoT with digital twins also strengthens exception detection and scenario planning, especially when paired with Predictive Analytics Inventory signals to test reorder policies under real constraints.

Dr. Henrik Olafsson, Head of IoT Solutions, Nordic Freight Labs: "Putting a digital twin over a distribution center is like rehearsing a fire drill for every possible disruption."

Where it shows up first

Cold chain monitoring with proactive alerts to reduce waste

Predictive maintenance for conveyors, forklifts, and refrigeration

Fleet optimization using live location and dwell-time data

Warehouse layout testing before moving racks or labor zones

Practical recommendation

Pair an IoT rollout with a SaaS digital twin pilot for one regional DC to validate data flows, exception rules, and ROI—an approach now accessible to mid-market firms as platforms become simpler and subscription-based.

Sustainability Tech & Circular Economy Solutions (Sustainable Logistics Essential)

By 2026, sustainability shifts from brand messaging to an operational mandate. EU mandates and broader mandatory reporting, plus investor scrutiny, are accelerating sustainability tech adoption across Sustainable Logistics Operations. As Evelyn Hart, VP Sustainability, Evergreen Brands, notes:

"Sustainability is no longer 'nice-to-have' — investors and regulators expect verifiable action using technology."

From ESG goals to ESG Compliance Supply Chain execution

Carbon tracking, reverse logistics automation, and circular economy platforms are becoming core systems of record for an ESG Compliance Supply Chain. AI, blockchain, and IoT help create credible, auditable data by linking shipment events, energy use, and supplier activity to emissions factors—turning ESG reporting into a repeatable process.

Tools that make Sustainable Logistics Essential

Carbon calculators embedded in TMS/WMS to estimate emissions by lane, mode, and carrier.

Digital Route Planning to cut empty miles, reduce fuel spend, and improve on-time performance.

Sustainable packaging systems that right-size cartons, reduce void fill, and track packaging reuse.

Renewable energy integration for warehouses (solar, storage, smart meters) to lower operational emissions.

Reverse logistics automation to route returns to refurbish, resale, recycle, or parts recovery.

What still makes it hard

Measuring Scope 3 remains a technical and governance challenge, especially across multi-tier suppliers with uneven data quality. Partner alignment is also difficult: circular programs require shared incentives, clear return policies, and agreed data standards. Upfront capital for sorting, refurbishment, and take-back networks can slow adoption.

Practical next steps

Start with high-impact pilots—route optimization and packaging reduction—then expand to returns and circular platforms. Define metrics that match regulatory and investor expectations (emissions per shipment, empty-mile rate, packaging intensity, recovery rate) so progress is measurable and defensible.

Predictive / Prescriptive Analytics, Collaborative Platforms & Control Tower Evolution

From dashboards to decisions: Predictive Analytics Inventory at scale

In 2026, leaders are moving past descriptive reporting toward analytics that recommend—and sometimes execute—actions. Modern models combine big data and machine learning to improve demand sensing, detect disruption risk earlier, and optimize inventory across locations. Research shows analytic systems that ingest external signals materially improve forecast accuracy and risk detection, especially when they blend weather, market trends, social sentiment, economic indicators, and geopolitical data.

Automatic inventory rebalancing between DCs and stores

Price and promotion optimization tied to supply constraints

Supplier risk alerts based on performance, news, and lead-time shifts

Karen Ito, Director of S&OP, Axis Manufacturing: "When the control tower tells you which DC to top up and why, planners can focus on exceptions — not spreadsheets."

Collaborative Ecosystem Platforms that connect partners in real time

Multi-enterprise, API-first platforms are becoming the practical way to run CPFR, shared transportation, and real-time supplier collaboration. They reduce information gaps, but they also require clear governance for data privacy, access controls, and common definitions. Platform consolidation and standards will determine how easily partners can collaborate in real time—especially across different TMS, WMS, and ERP stacks.

Control Tower Evolution into an active decision engine

Control towers are shifting from “visibility hubs” to simulation-led orchestration layers. With Supply Chain Network Optimization, they can test options and auto-trigger mitigation, such as rerouting freight, switching carriers, or adjusting inventory buffers. Cloud delivery is also lowering barriers, so small and mid-sized firms can access advanced analytics while automation augments teams—freeing planners for higher-value work.

Cybersecurity, Resilience Technology & Quantum Computing (Early Stage)

As supply chains become more connected through cloud platforms, IoT, and partner APIs, Cybersecurity Supply Chain risk rises fast. The threat landscape now includes ransomware, data breaches, third-party compromises, and infrastructure attacks. By 2026, advanced cybersecurity is standard, not optional—customers, insurers, and regulators expect proof of strong controls and fast recovery.

Dr. Michael Rao, Chief Information Security Officer, Harbor Freight Logistics: "Resilience is digital and physical — invest in cybersecurity like you invest in visibility."

Security and Supply Chain Resilience Tools That Matter

Zero-trust architectures, AI-driven threat detection, and incident automation are becoming core capabilities for Supply Chain Risk Management. SIEM systems and third-party risk platforms help teams spot supplier weaknesses, reduce dwell time, and respond faster when an incident hits. For layered defense, many organizations combine blockchain-based authentication, strong encryption, and multi-factor access controls—especially for shared data and connected devices.

Quantum Computing: Early Pilots, Real Learning

Quantum Computing remains experimental in 2026. Quantum pilots will inform future optimization architectures but will not replace classical computing yet. Most activity will be proofs-of-concept for complex route optimization, network design, and next-gen cryptography, often accessed through cloud services such as IBM Quantum, Google Quantum AI, Amazon Braket, and Microsoft Azure Quantum.

Practical Actions for 2026

Harden IoT endpoints (device identity, patching, segmentation).

Adopt zero-trust for users, devices, and partners.

Run quantum-readiness pilots to validate optimization proof-of-value.

Practical Roadmap: Assess, Prioritize, Pilot, Scale

Assess: benchmark maturity and define the problem

Leaders should start by benchmarking supply chain tech maturity across planning, execution, data, and security. The goal is to identify gaps and map each technology to a clear business problem—such as late supplier signals, weak visibility, or slow decisions. A Supply Chain Planning Platform assessment should also review master data quality, integration limits, and where S&OP Process Automation can remove manual handoffs.

Prioritize: focus on impact and readiness

Not every trend belongs on the 2026 roadmap. Teams should rank initiatives by business impact, readiness, and time-to-value. Common high-return starting points include Inventory Policy Adjustments driven by better forecasting, and targeted Augmentation of Workforce through robotics or AI copilots in planning and procurement.

Pilot: prove value before scaling

Pilots reduce risk and clarify ROI before larger investments. A pilot should be small, measurable, and integrated with real workflows (not a lab demo). Vendor partners should support integration, data access, and change management.

Ravi Desai, Principal Consultant, ChainShift Advisors: "Start where you can measure impact quickly — a well-run pilot beats a flashy roadmap without ROI."

Scale: govern with metrics, data, and training

Scaling requires strong data foundations and training—often the difference between a successful rollout and stalled adoption. Cross-functional teams (IT, operations, finance, procurement) should set governance, define success metrics, and avoid common pitfalls like poor data quality or trying to deploy too many tools at once.

Wild Cards & Thought Experiments

Wild cards are not “what-ifs” for fun; they are practical tools to stress-test plans and expose hidden dependencies like single-source suppliers, fragile carrier capacity, or a legacy ERP that cannot support real-time decisions. As Noah Green, Strategy Lead, ForwardOps Studio, notes:

"Treat bold scenarios as exercises — they reveal the operational weaknesses your dashboards miss."

Scenario Planning Capability: the 20% nearshoring shock

Consider a regional port outage that forces immediate nearshoring of 20% of imported SKUs. A strong Scenario Planning Capability would use a digital twin to simulate new supplier lead times, labor needs, and network costs within hours, not weeks. Agentic AI could then propose new reorder points, re-slot warehouses, and rebook transportation. In this model, Autonomous Agents Logistics is less about replacing people and more about compressing decision cycles when the clock is running.

Exception Detection Supply Chain: the nervous system analogy

To make complex tech easier for cross-functional teams, think of the future supply chain as a nervous system: IoT sensors are the neurons, AI is the brain, robotics are the muscles, and blockchain is the DNA that proves identity and history. The goal is faster Exception Detection Supply Chain—spotting temperature drift, supplier delays, or demand spikes early enough to act.

“We treated technology like a menu, not a recipe.”

This fictional CFO line captures a common trap: buying tools without designing how they work together.

A two-week workshop that ends in a board-ready pilot

In a two-week rapid pilot, leaders can map pain points, choose one tech lens (digital twin, AI agent, or IoT), define success metrics, and run a lean test. Workshops accelerate decision-making, reduce pilot fatigue, and end with a simple ROI story the executive board can approve for scale.